For many, a denim pilgrimage to Japan is the result of years of yearning, dreaming, saving, and no small measure of spouse-convincing. A special chance to explore the birthplace of many of your favorite denim brands, perhaps being lucky enough to visit the brand’s main shop or even the company headquarters. The truly dedicated will even work in a day trip to jeans Mecca itself, the small and somewhat far-flung town of Kojima in Okayama prefecture. A bit of work to get to, but by no means impossible.

To actually get into one of the few small remaining ‘hataya’ however (the Japanese term for a weaving mill) where your favorite denim is smashed together on vintage looms has been basically impossible, outside of a personal escort by a jeans brand owner who uses that particular mill (refer back to “basically impossible”). And even if you could somehow arrange such a tour, it would most likely be a no-cameras, no-information-divulged affair, the hataya careful not to reveal information that each jeans maker may not want to be public knowledge. So we’ve basically had to be content with simply buying and wearing our favorite denim, the genesis of the material itself remaining, for the most part, rather mysterious.

Thanks to the Japan Blue/Momotaro group however, this is no longer the case. Realizing the benefits of opening this rarely-seen but vital link in the jeans making chain to the general public, the father-and-son duo of Hisao and Katsu Manabe decided to move their weaving factory from a rural location 40 minutes out of Kojima, right into the heart of their operation located about 100 meters from Kojima train station, directly adjacent to their company headquarters.

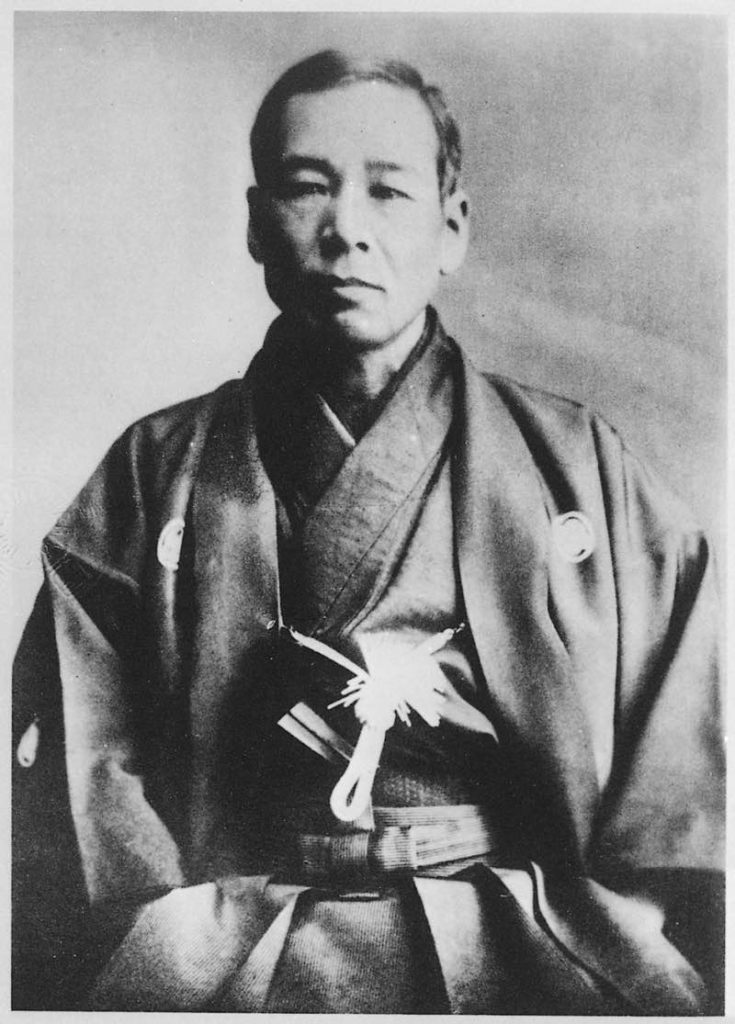

Perhaps I should back up a bit here. Before Momotaro or Japan Blue even existed, Hisao Manabe had established his own vintage shuttle loom mill in Kojima, known then and now as Collect Mills. For years Manabe-san used his vintage Toyoda looms to produce high-quality denim for other jeans makers, many of whom were the ones leading the denim revival in Japan during the mid-90s. At some point however, Manabe-san decided that he too would like to start making jeans with his own material, and thus Momotaro (and later, Japan Blue) were born. To my knowledge they are still the only jeans makers who actually own and run their own hataya.

Business grew and denim production continued on in their factory in Nakaune, Okayama. Recently however, due to the fact that more and more of Collect Mills’ customers were wanting to actually see how the denim they were buying was produced, and Manabe-san also wanting to give Kojima itself a tourism boost, he made the decision to move their nine vintage Toyoda looms into a new building, right next to to the JB headquarters, minutes from Kojima station.

I was lucky enough to be invited to the press release and official opening of the new mill and was impressed by the new facility, and also by the fact that they were now planning on opening it to the general public. It is now possible, through reservation, to actually go inside a working weaving mill that uses vintage shuttle looms to see, hear, and smell them in operation. For free. And even if you don’t have a reservation, you can still show up during business hours and view the machines in operation from just outside the mill, through a large window installed for such a purpose.

After Manabe-san had given his talk to the Japanese press there was a ceremonial countdown and he proceeded to fire up one of the looms. The noise was intense (to put it mildly), the rhythmic movements hypnotic. Ka-chon! Ka-chon! Ka-chon! By the time all nine machines were running, the noise was deafening and left me wishing I’d brought the earplugs I had briefly considered taking before leaving them at home.

The machines themselves are Toyoda GL9s. There are nine of them operating inside the mill, with two extras kept outside for parts. They are maintained by a master craftsman, 72-year-old Uchida-san, who told me he has been working on Toyoda looms for a total of 54 years now.

He is assisted by 27-year-old Yamamoto-san who has been working and training on these very machines since he was 18. More mills are now bringing on young trainees to learn from these aging masters to ensure we will have quality selvedge denim for years to come.

After the conference I headed out to lunch with Katsu and Hisao-san and learned that Toyoda looms were first invented in 1924 by Sakichi Toyoda, their model designations starting with the first “G” model and eventually running up to the “GL10” which ceased production in 1989.

Back in the day, these “Non-stop Shuttle Change Automatic Looms” were a huge advancement in weaving tech, now able to manufacture fabric at 15 to 20 times the rate of then-conventional looms. The shuttle inside the loom will make about 170 round-trips per minute, and the machines are also equipped with loom winders which automate the winding process and the replenishment of weft yarns to further increase production efficiency. Since then, times have changed of course and these shuttle looms can only operate at less than one-fifth the speed of modern power looms.

Over our delicious meal of local ramen and octopus rice I was able to ask Manabe-san a few things I’d always wondered about. I found out that their GL9 looms will make about 5 meters of denim an hour, nearly enough to make two pairs of jeans. Another advantage of these looms is that they are able to weave even relatively thick yarns well, and can be tuned slightly to create unevenness in the surface of the denim, due to a kind of ‘swelling’ in the weft that is similar to those textures found more commonly in handwoven fabric.

Through our conversation it was obvious how much love the Manabe family holds for Kojima. While opening their mill to the public will undoubtedly increase interest in their own brands, it seemed that their main objective was to increase interest in Japanese denim in general, and in their little seaside town. This same love was the impetus for Manabe-san creating Jeans Street years ago – trying to save the town from depopulation and revive interest in what has always been a historic fabric producing area. When I asked how hard it was to move the delicate vintage machines from the old location to the new, Katsu answered, “It was extremely difficult. But we really hope that our new mill will attract more people to Kojima and give denim fans a chance to finally see how denim is actually produced. ” I think it will do both of those things.

If you do have the chance to visit Kojima, take some extra time to wander over to the mill and have a peek through the window. It really is quite an experience to see and hear the old machines banging away, creating the selvedge denim we all know and love.

Kojima Denim Mill is open from Monday to Friday, from 10:00 to 12:00 and again from 13:00 to 17:00. Their email address is: inquiry@japanblue.co.jp

Oh really great to read! Momotaro and Japan Blue are one of my favorites out there! Great ?